An in-depth look at collaboration between CAI Machine and Klüber Lubrication in China for beverage cups printing

As must-haves many Chinese rely on to stay energized all day long, coffee and milk teahave gained unprecedented popularity in the market over recent years. Amidst the postCOVID-19 era, rising health consciousness among the consumers and increasinglyfierce competition among the brands, are all putting greater demands on theseproducts: safer and healthier, as well as tasting and looking better. In this regard,perfectly printed packaging which is both aesthetic and functional plays an integral role. Forready-made beverages that are expected to look fashionable and premium, such ascoffee and tea drinks, beautiful cups are essential to convey the brands' sense of value- and advanced printing processes and equipment are essential to accomplish this.

Photo: Plastic beverage packaging printed with dry offset process (courtesy of Suzhou CAI Machine Group Co., Ltd.)

Presently, the mainstream printing processes used in plastic beverage cups include dry offset as well as shrink sleeve and in-mold labeling. Among them, dry offset is popular due to its relatively low cost, excellent environmental performance and other edges. Specifically, dry offset is more efficient and faster than other printing processes, and does not require a secondary process, which drives down the costs. And because it does not require as many materials as other processes, dry offset is also conducive to ecofriendly recycling. So, in today’s market, where there is an increasing focus on the “quality-price ratio”, this printing process has become the obvious choice for manufacturers of beverage cup packaging to meet quality, cost and environmental requirements. So, what major considerations do packaging suppliers and brands need to take upon specific applications?

Focus: high performance

MA Shun, chairman of Suzhou CAI Machine Group Co., Ltd., one of leading suppliers of dry offset printing equipment in China, summed it up precisely: “The first is production stability; the second is production speed and, needless to say, safety — after all, cups come in direct contact with beverages.” Always committed to providing a holistic solution on decorative packaging printing, CAI now has many customers from both China and abroad. In the beverage industry, it serves most of the mainstream Chinese brands and some international ones, all of which are familiar to the end consumers. The reason why CAI has been so widely recognized and praised is down to the performance advantages of its equipment: stability and reliability, high efficiency, high precision, environmental protection, safety and easy operability.

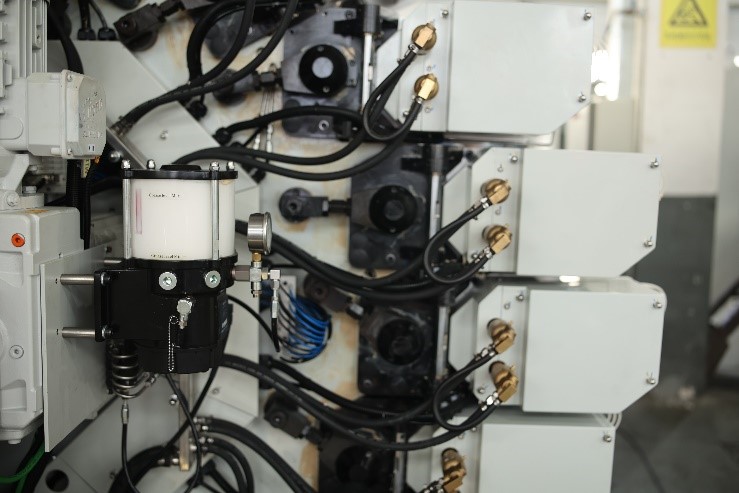

It goes without saying that developing and producing such a printing machine that can meet the full range of needs places extremely high technical demands on the suppliers. In CAI’s view, it is important to first consider every component and aspect of equipment production in a holistic way, including lubrication. As one of the key considerations, in fact, lubricants are highly relevant to all aspects of equipment performance. Based on the results of a thorough evaluation, CAI has finally chosen Klüberfood NH1 11-572, a high-performance and multi-purpose lubricating grease from Klüber for the food processing and pharmaceutical industries. This lubrication solution not only meets the stringent requirements on food safety, but also saves considerable costs, extends the lubrication period and facilitates operation.

Analysis: efficient lubrication solution

So, how to ensure and further enhance the performance of the printing machinery with an efficient lubrication solution? The following is a comprehensive analysis of the successful case of collaboration between CAI and Klüber on helping brands strand out with perfectly printed beverage cups.

Food safety, always a top priority

The choice of lubricants is the key to ensuring safety. Food-grade safety is the most fundamental requirement in all aspects from grease to printing ink. When it comes to lubricants, achieving the relevant professional certification is one of the important reference standards for the selection made by CAI. In this regard, Klüberfood NH1 11-572, a lubricating grease from Klüber which is NSF H1-registered and fully complies with FDA regulations, has been developed for applications in the food processing, cosmetics and pharmaceutical industries. It can help further enhance the safety of CAI’s machinery and equipment in a reliable manner.

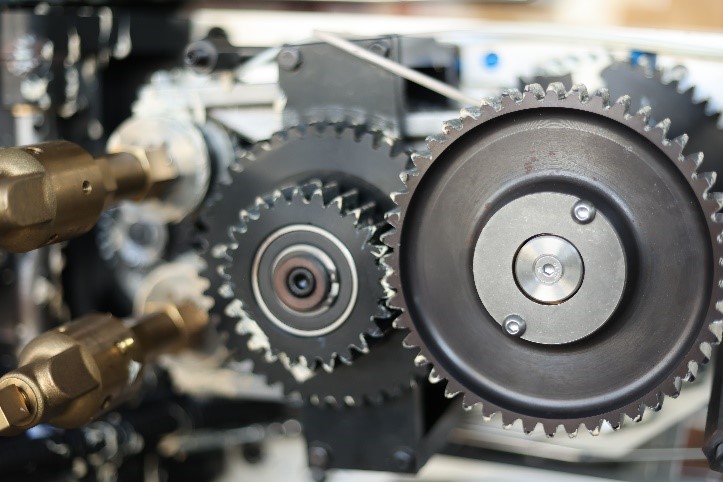

In addition, the excellent adhesion of the lubricating grease from Klüber further enhances safety — as it reduces the risk of dripping and further reduces potential safety hazards during production. With its strong anti-wear properties, excellent resistance to water and oxidation, this grease also protects equipment roller bearings and gear parts against corrosion. All the features help to reduce the cost of equipment maintenance while ensuring safety.

Photo: CAI S608 series high-speed 8-color paper cup positioning press with automatic lubrication system

Photo: Gear parts lubricated with Klüber food NH1 11-572, a multi-purpose food-grade lubricating grease from Klüber (internal structure)

High-speed stability is highlighted

CAI understands “maintaining stability” profoundly, as there have been cases where some gears were obstructed and the whole equipment could not operate normally due to improper lubrication. The equipment manufacturer’s solution to this pain point is to use an automatic lubrication system to pump the grease into the exact places in a quantitative manner to ensure proper operation and to give the end customers peace of mind. In this regard, Klüberfood NH1 11-572, a lubricating grease from Klüber featuring good pumpability, ensures efficient and quantitative lubrication of the equipment.

In CAI’s view lubrication is crucial to all moving parts of the entire equipment, and its influence on the operational performance is reflected in various aspects: both stability and speed. For instance, during the printing process, the main bearings in the equipment will be running at high speed for a long time and the temperatures thus rise. In response, CAI applies greases to reduce friction, along with installing water cooling devices on the equipment, to ensure stable bearing operation.

High precision, winning in detail

In this day and age, where the “Beauty Value” economy is increasingly prevalent, the consumer trend of paying a premium for “good looks” has led beverage brands to be picky about how well their cups are printed, which in turn has pushed suppliers to strive for perfection in high-precision printing. According to Ma, leading brands now pay attention to each detail when evaluating print quality, including their logos and even seemingly simple QR codes. To realize such high-definition printing on curved packaging cups efficiently requires the highest technical performance of the equipment.

One of CAI’s tips for successfully achieving high precision while ensuring high-speed stability is to take lubrication into account; because poor lubrication makes it difficult for high precision equipment to perform well. Currently, Chinese manufacturers still mainly rely on manual methods to maintain print speed while avoiding reduced accuracy and increased scrap rates, which, however, puts great pressure on the operators and inspectors. “With the adoption of technical solutions including Klüber lubricants, CAI has successfully solved these problems and become one of the cost-effective printing solution providers in the eyes of leading brands,” Mr. Ma pointed out.

Doubling down on environmental sustainability

Looking ahead to the future, the Chinese beverage market will be continuously moving towards the trend on health and premiumization, pushing packaging companies to act in the same way. As an “upstart”, ready-made beverages are particularly active in using packaging to convey the message of “healthy + tasty + beautiful”, which requires suppliers to further explore and experiment with new printing technologies and equipment. For example, CAI believes that full-page printing, which is already widely used abroad, is expected to be promoted first in China’s beverage industry, such as yogurt and dairy sectors.

Looking across the entire food packaging market, the environmental sustainability trend will also be going strong. As an important part of this, eco-friendly materials are increasingly being used in packaging. CAI also noticed that most of its high-end customers have started using biodegradable materials such as PLA and molded pulp, recyclable PET and aluminum. So the company strives to ensure that its equipment not only runs efficiently and accurately, but also adapts to the specific properties of various eco-friendly materials.

Klüber Lubrication contributes to the environmentally sustainable solution with its lubricants that meet the various compliance requirements of the customers. As a lubricant manufacturer with “Gold Award” by EcoVadis, Klüber Lubrication always integrates the needs of its customers’ industries for sustainability into its own business and R&D strategies.

EcoVadis is an independent rating platform that provides overall Corporate Social Responsibility (CSR) ratings

In general, China’s new consumption landscape is becoming more competitive, prompting a constant quest for excellence and affordability, while global climate and national policies are demanding more actions on environmental protection and sustainability. All have been raising the bar on beverage packaging, including decorative printing: to ensure safety while being more aesthetic and eco-friendlier, thus delivering beverage brands more attractive “looks” and consumers better experiences. This can only be achieved with allinclusive technical support from upstream suppliers. The CAI x Klüber partnership is a testament to this. Together, the two companies have developed efficient lubrication solutions to ensure high performance of printing equipment processes, resulting in standout beverage packaging in a more cost-effective way.

About Suzhou CAI Machine

Suzhou CAI Machine Group Co., Ltd. specializes in developing and manufacturing high-speed precision dry-offset printing machines. It aims to help customers deliver the brand and product messages by providing efficient clear printing decorations on the surfaces of plastic containers. Thanks to the full-color printing machines, the high-definition pictures, texts or QR codes can be clearly displayed on the surfaces of the plastic containers for a wide range of products such as milky tea, coffee, juice, yogurt, and ice cream. Meanwhile, it can also be applicable to plastic caps, plastic cylinders, flowerpots, aluminium pots, and other packages.

CAI Machine keeps improving and innovating the current technologies and equipment based on many years’ experience in the industry to become an industry model in terms of machine functions, printing quality and production efficiency in China. We remain committed to the principle of being demand and result-oriented, pursuing leading technologies and excellent services to provide printing solutions of cost efficiency for customers.

For further information, please click www.caimachine.com

About Klüber Lubrication

Klüber Lubrication is one of the world's leading manufacturers of speciality lubricants, offering high-end tribological solutions to virtually all industries and markets worldwide. Most products are developed and made to specific customer requirements. During its over 90 years of existence, Klüber Lubrication has provided high-quality lubricants, thorough consultation and extensive services, which has earned it an excellent reputation in the market. The company holds all common industrial certifications and operates a testing section hardly rivalled in the lubricants industry.

Klüber Lubrication, set up as a retail company for mineral oil products in Munich in 1929, is today part of Freudenberg Chemical Specialities SE & Co. KG, a Business Unit of the Freudenberg Group, Weinheim. Klüber Lubrication has about 2,400 employees in more than 30 countries.

For further information, please click www.klueber.com

Post time: Dec-14-2022